Hundegger SPM-2

The flexible revolutionary throughfeed centre for panel processing

No other system comes close: Sawing, milling, drilling, grooving, labelling – the Speed Panel Machine SPM-2 from Hundegger is the innovative throughfeed concept for fully automatic panel processing of a wide variety of different materials. The SPM-2 is not only able to format panels of all types, but also performs all necessary processing operations quickly and precisely so that the panels are ready for installation. Whether individual pieces or high-volume production – the range of processing capabilities and materials is almost unlimited. The SPM-2 was specifically designed as an efficient system

for wall production in timber frame construction and for facade engineering. Furthermore, it is the flexible solution for panel production in formwork construction, in interior construction and in packaging. The modular design allows the machining to be equipped individually and upgraded at a later stage – right up to configuration as a flexible production cell with integrated panel storage. Different units are available for various processing tasks.

SPM-2 in six variants

- Panel size 1,300 x 3,200 mm

- Panel size 1,300 x 4,500 mm

- Panel size 2,600 x 3,200 mm

- Panel size 2,600 x 6,000 mm

- Panel size 2,800 x 6,000 mm

- Panel size 2,800 x 8,000 mm

Panel processing from a thickness of 5 to 120 mm and an individual weight up to 500 kg

THE HIGHLIGHTS OF THE SPM-2

Simple handling with complete machining

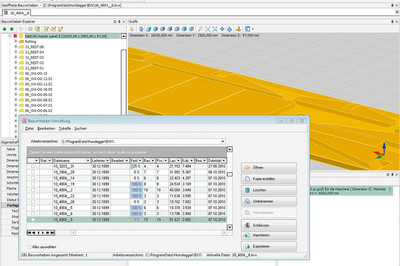

The data required for processing can be imported automatically by the CAD system or entered at the operating terminal using the keyboard and mouse. The SPM-2 performs all further processing operations fully automatically – including material infeed and outfeed. Innovative panel transport makes expensive vacuum clamping systems unnecessary.

- Cutting at any angle

- Milling of profiles and openings of any shape or form

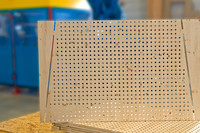

- Drilling of various diameters

- Countersunk holes of various diameters

- Edge formatting e.g. rebbat joints or drywall chamfer

- Inkjet-marking, numbering, barcodes, customer logos

VIDEO SPM-2

SPM-2 machining examples

The revolutionary concept for panel processing

COST-EFFECTIVE IN TIMBER FRAME CONSTRUCTION

The SPM-2 is a minor sensation in the world of panel processing machines. It paves completely new ways in timber frame construction. Its extreme flexibility with respect to the materials to be processed makes the SPM-2 an outstanding processing system for wall production. The SPM-2 retrieves the data directly from the CAD program. In this way, exterior and interior panelling is manufactured precisely to the required dimensions. The often considerable offcut disappears almost entirely!

HIGHLY EFFICIENT IN FACADE ENGINEERING

For either a new facade or curtain walling - the SPM-2 simplifies facade engineering considerably and optimises the material costs here too. It can be used for processing many different materials. This makes it an indispensable partner when it comes to the megatrend of thermal insulation, for example. Scan facade and produce a precisely fitting panel The data generated using a 3D laser scanner is fed into the CAD system and automatically processed further by the SMP-2. In this way, precisely fitting panels are produced for the facade – fully finished, without the need for any reworking.

FLEXIBILITY FOR ACOUSTIC SYSTEMS

INTERIOR FITTINGS AND STAIRS

Stair construction

With the optimization/nesting program, the panels are optimally partitioned and thus the waste is minimized. Even the milling of staircase steps for a spiral staircase is possible without re-tooling the SPM-2 Speed-Panel machine.

Interior fittings

With its versatility, the SPM-2 also scores points when it comes to interior fittings.

Various processing units for more flexibility - according to your needs

Verschiedenste Bearbeitungsaggregate für mehr Flexibilität

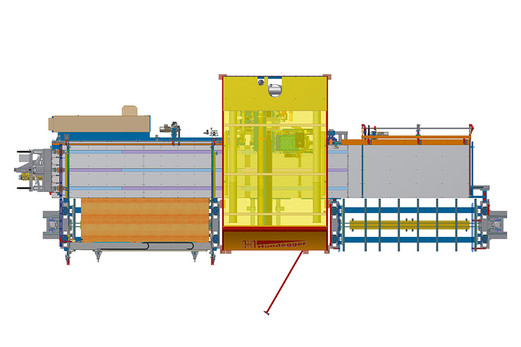

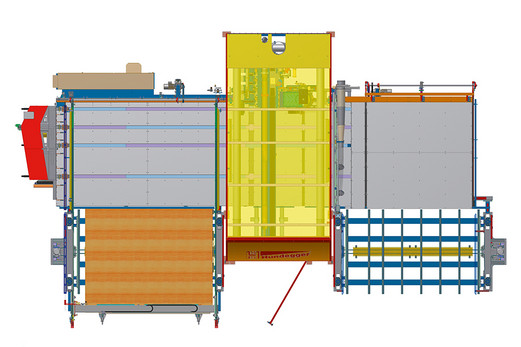

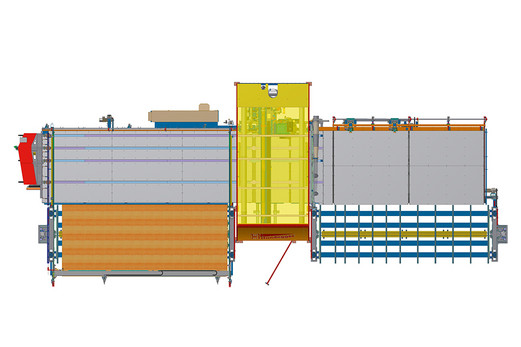

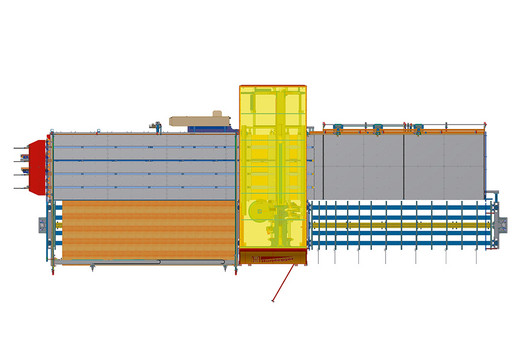

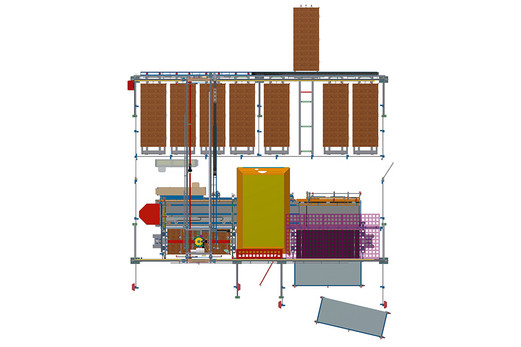

The installation variants, according to your needs

Installation examples and dimensions

Automation of the Hundegger SPM-2

Für jede Anforderung gerüstet

Lift tables and part infeed

The electronically controlled lift tables are responsible for loading and removal of the parts. They can be loaded and unloaded from the front using a forklift or from above using a crane. Panels to be processed are loaded in packets and conveyed plate for plate fully automatically into the machine.

![[Translate to Englisch (Deutschland):] [Translate to Temp:] SPM2_EN_19_11_2021 [Translate to Englisch (Deutschland):] [Translate to Temp:] SPM2_EN_19_11_2021](/fileadmin/user_upload/Prospekte/SPM/SPM2_DE_19_11_2021/SPM2_DE_19_11_2021.jpg)