The all-rounder for processing and assembly of insulated timber framed elements for construction

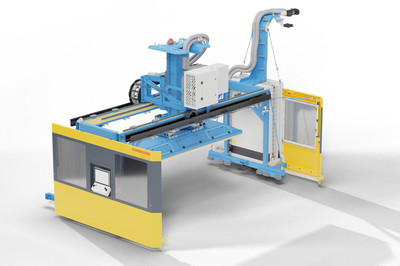

Its compact gantry design with integrated control cabinets ensures optimal space usage in any factory environment.

The modular design allows for customized configurations and maximum flexibility. The powerful processing unit guarantees precise manufacturing of wall, roof, and ceiling elements—ensuring repeatability and accuracy. An automatically controlled tool changer system enables optimal use of all types of fasteners. Full integration into the CAMBIUM software platform simplifies operation and control, helping user-friendliness and productivity.

The Hundegger WALL-Master is available in three powerful versions:

- Hundegger WALL-Master 3200

- Hundegger WALL-Master 3800

- Hundegger WALL-Master 4500

The WALL-Master gantry features a torsion-resistant welded box construction that moves via servo motors on X-axis guide rails for high positioning accuracy. Integrated control cabinets and a mobile control panel ensure intuitive operation and minimal space requirements. The direct connection between the gantry and table structure forms a stable unit. Specially designed linear guides and seals prevent dust ingress, while the rail design allows easy access to the element table.

The direct connection between the element bridge and the table structure creates a stability. Linear guide carriages with specially designed scrapers and seals reliably prevent the ingress of wood dust. In addition, the well-thought-out rail design allows comfortable access to the element table, thus supporting efficient and precise production.

Max. travel speeds

- X-axis ~ 35 m/min

- Y-axis ~40 m/min

- Z-axis ~35 m/min

Max. element dimensions

- Length: depends on table size

- Width = 3.200 mm (WALL-Master 3200)

- 3.800 mm (WALL-Master 3800)

- 4.500 mm (WALL-Master 4500)

- Height = max. 550mm

HIGHLIGHTS OF THE WAM 3200 | 3800 | 4500

- Compact design, minimal space requirements even with turning system

- Innovative safety concept

- Future Expansion potential in terms of capacity and wall systems

- Compatible with various insulation systems:

- WAM-TL | WAM-TS | WAM-TC

- Powerful, air-cooled 3-axis spindle with 11 kW (Upgradeable to 4-axis and 5-axis)

- Up to 5 different fastening systems possible:

- nailing | stapling | screwing | pushing | and more

- Optional: component and table cleaning

- Flexible table solutions: intelligent table solution or on-site implementation

- Universal interface for fastening devices from any manufacturer

- Precise placement of staples at a statically correct angle

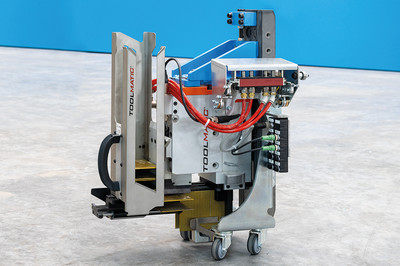

- Automatic tool change

Modular design

Highly efficient production and insulation of timber construction elements

Two Units. One Goal: Efficiency.

The new WALL-Master combines a high-precision processing unit with a flexibly deployable fastening module – for maximum productivity in timber frame construction. Thanks to automatic tool and device changes, the system adapts seamlessly to different wall structures and production requirements.

Whether milling, sawing, drilling, marking or fastening: intelligent technology ensures precise results with minimal setup effort.

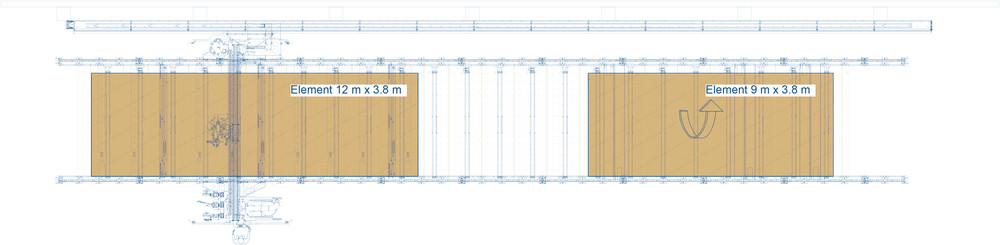

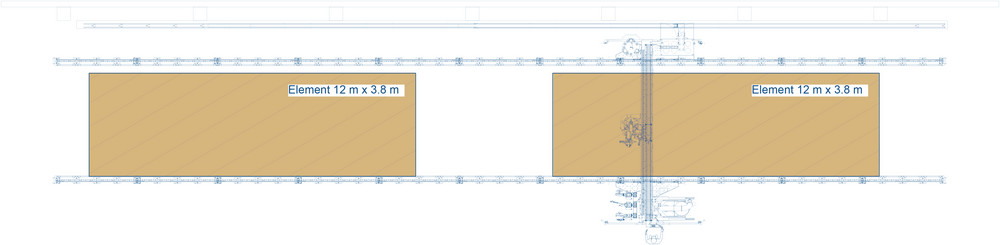

INSTALLATION VARIANTS

Individual solutions for all requirements

According to customer-specific production processes and spatial conditions, system solutions optimally tailored to customer needs are developed during the project phase.

WALL-Master Cut & Fastening with SMART-Table

Modular Design

Perfectly adaptable to your production method

Individually scalable table system

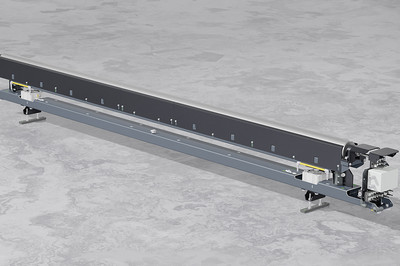

The flexible table solutions of the WALL-Master combine precise processing with efficient material flow.

The system can be individually adapted to different requirements. From fixed, liftable and lowerable modules with or without rollers to the SMART-Table solution – the ideal basis for efficient production processes.

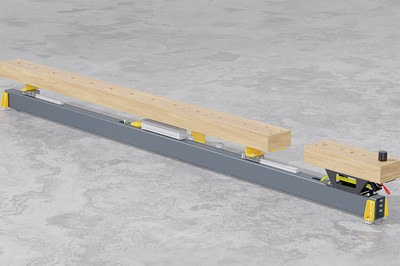

SMART-Table

The table system serves to securely fasten and process elements with the processing portal. With a grid size of 1,200 mm (distance between the rollers) and a working height of 550 mm, the table offers a load capacity of up to 100 kg/m². The individual table elements are mounted on the Halfen rails of the X-guide rail of the portal, ensuring stability and flexibility.

Three different insulation variants

Innovative insulation portals for maximum productivity

The three insulation portals Thermo Linked, Thermo Solo, and Thermo Cantilever offer innovative solutions for the efficient introduction of insulating materials.

Whether as a suspended portal, autonomous system, or flexible cantilever – all variants use the most modern blowing technology and are perfectly adapted to the requirements of element production. Thanks to control via CAMBIUM® and the use of a common rail system, they ensure maximum precision and flexibility.

WALL-Master Thermo Linked

The insulation portal, suspended from the WALL-Master Cut+Fastening, allows the introduction of insulating material via blowing technology. It uses the same rail system as the element bridge, is connected to the control system, and mechanically fixed. The machine weight is about 3 tons.

WALL-Master Thermo Solo

The autonomous insulation portal uses a torsion-resistant and bending- resistant welded construction and moves servo-motorically on the X-axis guide rails. With blowing technology for the introduction of insulating material and mobile control cabinets for minimal space requirements, it offers efficient solutions. The same rail system as the element bridge is used.

WALL-Master Thermo Cantilever

The cantilever allows the flock plate to traverse the entire portal and the flock portal to rotate by ±90°. This allows all contours of wall elements to be precisely filled, including narrow compartments, e.g., above window lintels. Even complex elements such as dormer cheeks can be efficiently flocked. The entire flocking process is controlled via CAMBIUM®.